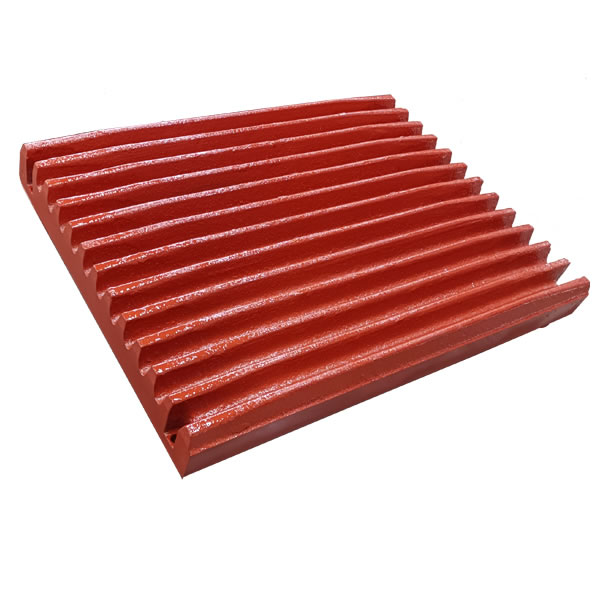

Diaphragm For Mill

OEM tailor design

Product name: Discharging device

Production process: Casting

Applicable machines: Ball mill/ semi-autogenous mill

Material types: High manganese steel, high chromium cast iron, alloy steel, etc.

Applicable industries: mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.