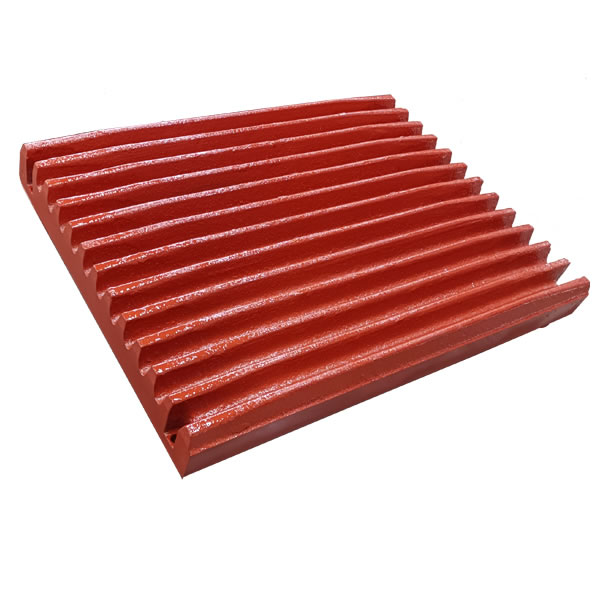

High chromium ceramic blow bar for Impact crusher

Material introduction of high chromium ceramic bar

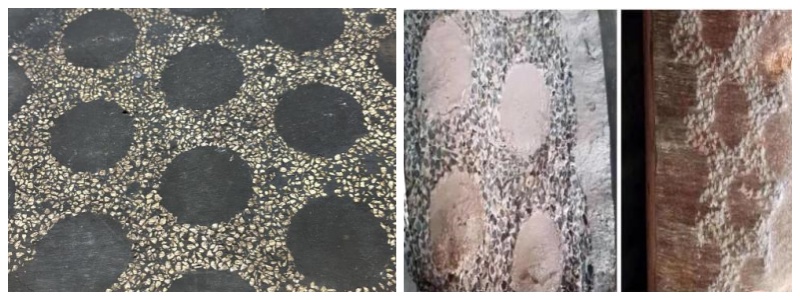

Ceramic metal composite wear-resistant material is a kind of casting infiltration technology to evenly distribute cermet particles on the working face of wear-resistant spare parts. By optimizing the chemical composition of high chromium wear-resistant materials, cermets are embedded in the easily worn parts to make them have excellent properties of wear resistance and high temperature resistance.

In the honeycomb structure of high chromium cast iron, because the hardness of ceramic (particle) is hv2100 and the hardness of high chromium cast iron is HV < 900, the ceramic metal composite is widely used in various wear fields, and its service life is 3-4 times longer than that of single high chromium cast iron. Thus, the running time of wear-resistant spare parts is prolonged, the maintenance times and time are reduced, and the production efficiency is improved.

Introduction of impact plate (plate blow bar) of ceramic metal composite impact crusher

Although high chromium wear-resistant cast iron has high wear resistance,but it needs more wear-resistant materials to prolong its service life when crushing materials with very high hardness, such as granite. In this case, high chromium ceramic composite products are a very good solution. Therefore, in view of the fact that conventional materials are not wear-resistant, we are committed to (Zhili) selecting high chromium cast iron ceramic composite materials, The wear resistance of the composite layer is 3-4 times that of the high chromium material.

Application of ceramics in high chromium blow bar

In the process of using ceramic products, because ceramic high chromium cast iron have excellent wear resistance that other wear-resistant materials can not match, it greatly reduces the consumption of user materials and the labor cost of replacing wear-resistant parts, and becomes the representative of a new generation of wear-resistant materials.

Hign chromium creamic compisite blow bar from ZHILI

Photos of ceramic blow bar at work

Ceramic blow bar after use

on-site mapping

In order to better serve users, we have professional sales engineers, who can survey all kinds of parts on site. Our foundry engineers design inlaid ceramic area according to the survey data and plate hammer wear area.

At present, there are 15 sales engineers i, who regularly go to the user's plant to communicate the use of products, survey new parts, and recommend appropriate wear-resistant materials and anti-wear solutions according to the actual working conditions, so as to solve the problem of fast wear raised by users in an all-round way.