Crusher Wear Parts Manufacturer——ZHILI New Material

Luoyang ZHILI is a globally advanced crusher wear parts processing center integrating research, design, production and sales. Started in 1992, it has a history of more than 30 years. ZHILI mainly produces crusher spare parts including hammer, liner, jaw plate, blow bar, mantle, concave, vertical mill roller sleeve, mill liner, OEM etc. Next, I will take hammer as an example to give a brief introduction to our company.

For hammer, the materials we can provide include high chrome, high manganese steel, bimetal composite, high manganese insert alloy bar, high manganese welding, alloy steel, high manganese insert alloy bar + welding, ceramic composite etc. At present, the crusher hammer materials on the market mainly include bimetal composite and high manganese steel. By matching the performance characteristics of the material with the requirements of the working part, the bimetal composite hammer solves the difficulty of a single material with high strength, high toughness and high wear resistance at the same time, and is suitable for good working conditions. Although the wear resistance of the high manganese hammer is slightly worse than that of the bimetal composite hammer, its high toughness and high safety performance solve the problem of the bimetal composite hammer being easily broken under harsh working conditions.

Crusher hammer produced by our company

In recent years, ZHILI has developed high manganese insert alloy bar hammer, and high manganese steel insert alloy bar and welding hammer,which improve the wear resistance of the high manganese hammer. At the same time, we also introduce ceramic-metal composite hammer. Ceramic metal composite wear-resistant material is a kind of casting infiltration technology to evenly distribute cermet particles on the working face of wear-resistant spare parts. By optimizing the chemical composition of high chromium wear-resistant materials, cermets are embedded in the easily worn parts to make them have excellent properties of wear resistance and high temperature resistance. This greatly reduces the consumption of user hammers and the labor cost of replacing hammers, and becomes the representative of a new generation of wear-resistant hammers.

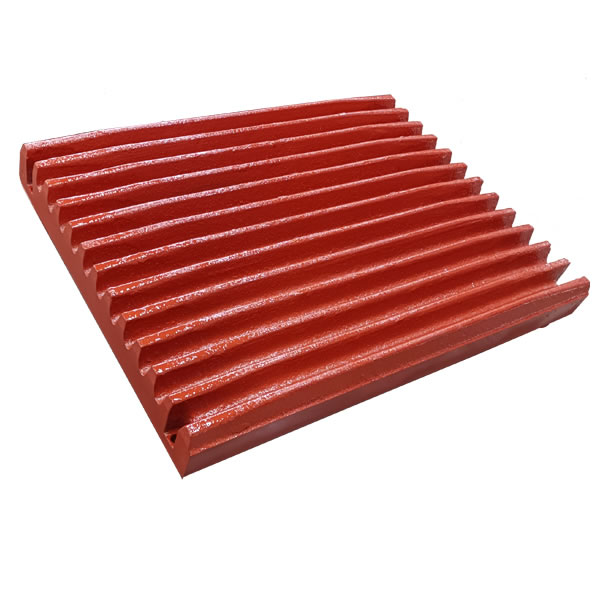

Crusher spare parts produced by our company

Different working conditions require selecting different materials. Hammers are used for crushing materials, but what troubles most enterprises is the short replacement cycle of hammers. ZHILI have an advanced team and equipment with the goal of improving the service life of hammers. The sales staff of our company have undergone professional training and will go to the customer site to recommend suitable wear-resistant materials and wear-resistant solutions based on actual working conditions, to solve the problem of rapid wear raised by users.

Our engineers visit customers in various countries for on-site inspections

Luoyang Zhili, a crusher spare parts supplier in China, mainly provides wear-resistant parts for hammer crushers, impact crushers, jaw crushers, cone crushers and other types of crushers. We use our years of experience to assure you that choosing ZHILI will not disappoint you. Welcome to leave your contact information, tell us your customization needs, and get a free quote.Our email:info@lyzhili.com .