Full analysis of ball mill liner materials: 6 materials advantages and disadvantages comparison, choose the right material to save 30% cost!

"For the same ball mill, why does the liner of plant A last for 2 years, but it is scrapped in 3 months in plant B?" A copper mining company chose the wrong liner material and processed high-hardness ore, and the annual loss cost surged by 2.17 million yuan. As a professional manufacturer with 30 years of experience in ball mill liner research and development, we deeply analyze the performance of 6 major mainstream materials to help you accurately match the working conditions, so that the liner life and production efficiency can be improved!

一、 "Performance Gene Map" of 6 Major liner Materials

1. High manganese steel liner (traditional overlord, being overturned)

Advantages:

✅ Excellent initial toughness (impact energy ≥ 150J)

✅ Affordable price

Disadvantages:

❌ Low hardness (HB170-230), fast wear rate

❌ Continuous impact is required to harden, and soft grinding conditions fail quickly

Applicable scenarios:

⚙️ Strong impact crushing (such as initial crushing of granite)

⚠️ Use with caution: fine grinding section, low impact conditions, corrosive environment

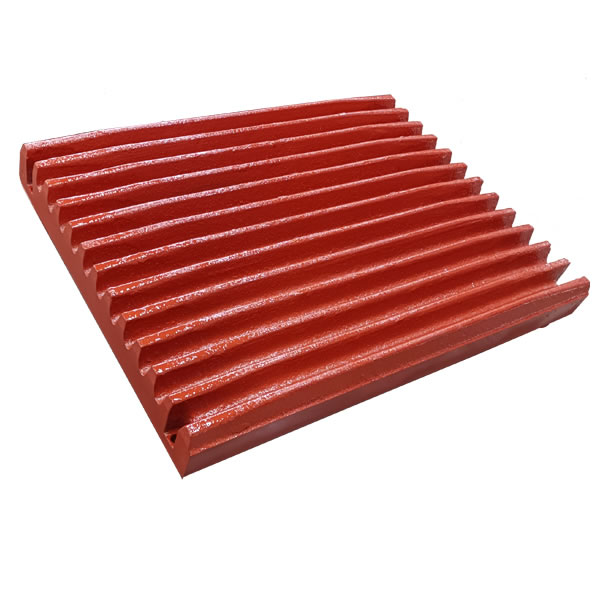

2. High chromium cast iron liner (king of wear resistance, technology iteration)

Advantages:

✅ Ultra-high hardness (HRC58-62), wear resistance is 1-4 times higher than manganese steel

✅ Carbide network structure blocks wear path

Disadvantages:

❌ High brittleness (impact toughness ≤ 8J), easy to break

❌ Difficult to repair by welding, high maintenance cost

Applicable scenarios:

⚙️ Medium and low impact fine grinding section (cement clinker, iron ore second stage grinding)

3. Rubber liner (silent guard, special working condition weapon)

Advantages:

✅ Noise reduction of 30dB, suitable for suburban factories

✅ Strong corrosion resistance (acid and alkali resistance pH3-11)

Disadvantages:

❌ High temperature difference resistance (>80℃ accelerated aging)

❌ Not suitable for large steel ball impact (ball diameter>60mm use with caution)

Applicable scenarios:

⚙️ Wet grinding, fine grinding of chemical raw materials, environmentally sensitive areas

4. Ceramic composite liner (cutting-edge black technology, the first choice for high-end players)

Advantages:

✅ Hardness comparable to diamond (HV1200-1500)

✅ Zero metal pollution, suitable for high-purity materials such as lithium ore and quartz sand

Disadvantages:

❌ High unit price (about 4-6 times that of manganese steel)

❌ Poor thermal shock resistance (easy to crack when temperature difference > 200℃)

Applicable scenarios:

⚙️ Ultrafine powder processing (above 325 mesh), food/pharmaceutical grade production line

5. Alloy steel liner (all-round warrior, large customization space)

Advantages:

✅ Strong adjustability (optimizing performance through Cr/Mo/V element ratio)

✅ High overall cost performance

Disadvantages:

❌ Long production cycle of non-standard parts (usually 15-30 days)

❌ Cost disadvantage of small batch procurement

Applicable scenarios:

⚙️ Polymetallic mines, complex wear conditions

�� Our "working condition diagnosis service": free element ratio scheme

6. Bimetallic composite liner (rigid and flexible, solving industry problems)

Structural innovation:

▶ Surface layer: high chromium cast iron (2-3mm wear-resistant layer)

▶ Base layer: high-toughness low-alloy steel

Advantages:

✅ Impact resistance increased by 70%, wear resistance maintained at high chromium level

✅ Can be repaired by welding, and the operation and maintenance cost is reduced by 40%

Applicable scenarios:

⚙️ High impact + high wear "double high" working conditions (such as gold mine semi-autogenous mill)

二、 Golden formula for material selection: 4 steps to lock the best material

STEP 1 Diagnose working condition properties

Material hardness (Mohs hardness/Praetz coefficient)

Impact energy (steel ball diameter × mill speed)

Corrosive medium (pH value, sulfide content)

STEP 2 Quantify wear type

Chisel wear (>50%): Select high-toughness material

Fatigue wear: Prioritize hardness

Corrosive wear: Composite protection is required

STEP 3 Dynamic cost calculation

Total cost = purchase cost + number of replacements × (downtime loss + labor cost)

STEP 4 Adapt to special needs

Environmental protection requirements: rubber/ceramic

Product purity: non-metallic material

Installation restrictions: lightweight design

If you need help with material selection, please leave a message on the web page and our engineers will contact you as soon as possible!

Through precise material matching, every liner board becomes a profit growth point!