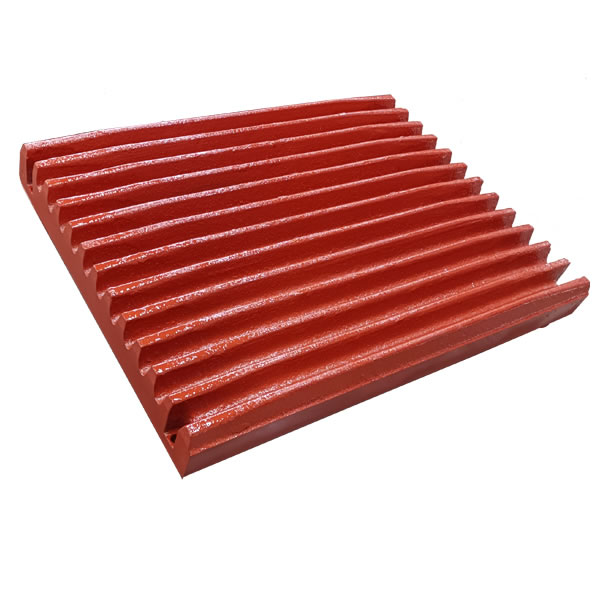

How to choose crusher hammer head?

I will professionally share with you and help you choose the right hammer for you to reduce the wear of hammer . Improve the productivity of your factory.

Of course, not just the crusher hammer head, blow bar,jaw plate,mantle and concave,vertical mill,liner and Hardox steel.I will share it with you in full.

Do you also have the following unpleasant experience when using the hammerhead?

1.Fragile when used due to material content control fails

2.Damage the equipment.When the wear-parts are broken during working

3.The service life is very short.

4.Increase the work cost of workers.Wear too fast makes workers frequently replace parts.

The reasons for the above problems are complex and can be roughly divided into the following types:

1.Quality problems caused by production.

During the production process, the manufacturer did not do good quality control, and the heat treatment technology was not mature enough, resulting in vacancy, cracks, and excessive sand adhesion on the hammer head.

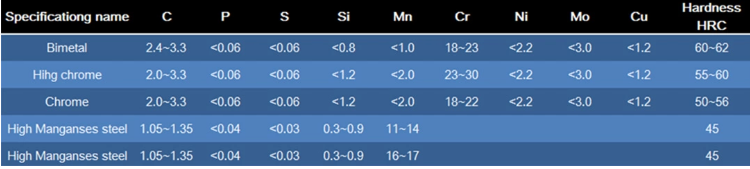

2.Choosing the wrong material to apply in an inappropriate working condition.

Different materials have different hardness, but we can not just pursue hardness, because hardness is inversely proportional to toughness, hardness is too high, the hammer is easy to be broken when working, we can only find a balance between hardness and toughness, so that the hammer reach the greatest advantages of materials in the corresponding working condition.

In addition to choosing a factory with more mature production technology and quality control, I think you can also learn about different materials to choose.

See you next time ,I will share you what kind of difference in materials.