Ceramic metal composite wear resistant material technology

Ceramic metal composite wear-resistant material is a kind of casting infiltration technology to evenly distribute cermet particles on the working face of wear-resistant spare parts. By optimizing the chemical composition of high chromium wear-resistant materials, cermets are embedded in the easily worn parts to make them have excellent properties of wear resistance and high temperature resistance.

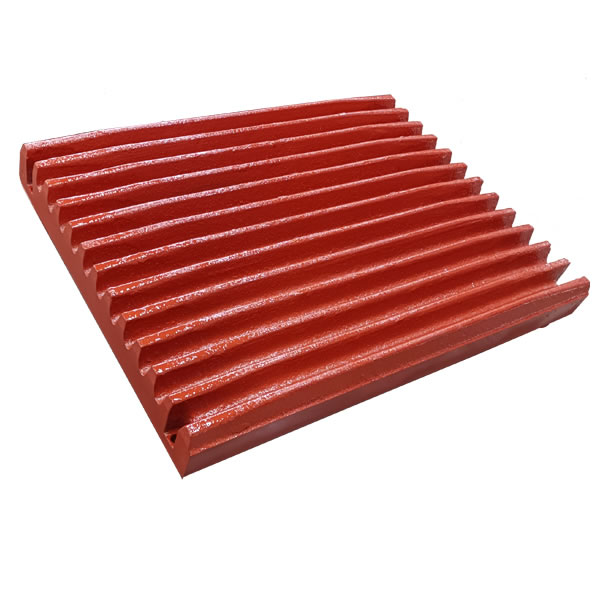

In the honeycomb structure of high chromium cast iron, because the hardness of ceramic (particle) is hv2100 and the hardness of high chromium cast iron is HV < 900, the ceramic metal composite is widely used in various wear fields, and its service life is 3-4 times longer than that of single high chromium cast iron. Thus, the running time of wear-resistant spare parts is prolonged, the maintenance times and time are reduced, and the production efficiency is improved.The main application products are grinding roller, grinding table, impact blow bar , hammer block, crusher hammer and conecrusher parts.

In the process of using ceramic products, because ceramic high chromium cast iron have excellent wear resistance that other wear-resistant materials can not match, it greatly reduces the consumption of user materials and the labor cost of replacing wear-resistant parts, and becomes the representative of a new generation of wear-resistant materials.

Luoyang Zhili New Materials established in 1992, is one of the world's leading wear-resistant materials processing center, providing high quality wearing parts service for mining, cement, power plant, steel, coal industries, etc.