Technical change of composite wear-resistant hammer heads

Crusher hammer head is the core part of crusher, bearing the important responsibility of crushing materials. In the process of crushing materials, the hammer head has to withstand huge friction and impact, and it is easy to wear, resulting in frequent shutdown maintenance and even replacement. In order to solve this problem, Luoyang Zhili New Materials Co., Ltd. developed the crusher ceramic hammer. To solve the problem of heavy wear for customers, the life of the hammer can be extended by more than 5 times.

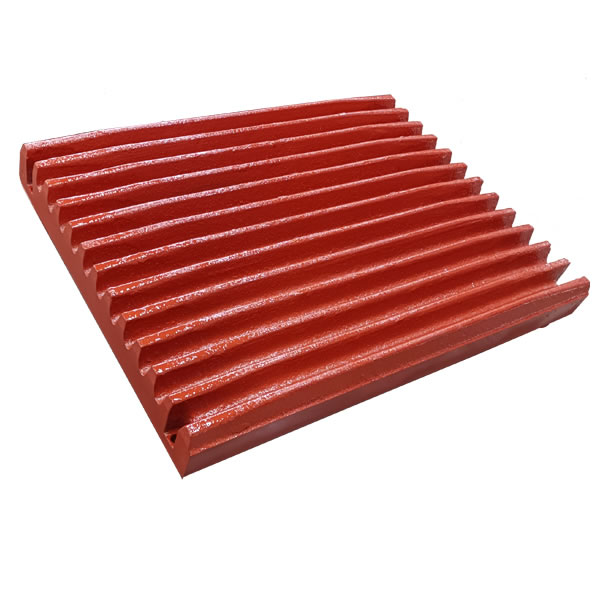

Crusher ceramic composite hammer mainly uses high chromium cast iron and other wear-resistant alloy materials. A certain amount of ZTA ceramic particles is combined on the heavy wear part of the hammer head. The alloy material supports the ceramic particles. Improve the overall toughness and impact resistance of the hammer.ZTA ceramic particles have high hardness, which can improve the anti-wear ability of the hammer head and extend the service life.

ZTA ceramic particles need to be compounded into the alloy material during the casting process of the hammer head, usually accounting for no more than 3% of the weight of the hammer head. In order to improve the performance of the hammer, the ceramic particles must be suitable and uniform in size, and the shape of the particles should be regular. ZTA ceramic particles and metal materials should be fully mixed, and different composite depths should be selected according to different working conditions. After many times of process improvement and field tests, master the ceramic metal composite technology. ZTA ceramic particle enhanced hammer head has been successfully applied in various mining crushers, sand making machines, sand making machines and other equipment.The hammer head of composite ceramic crusher has high impact resistance and high wear resistance, and is welcomed by many customers.