Analysis of wear-resistant accessories and functions of jaw crusher

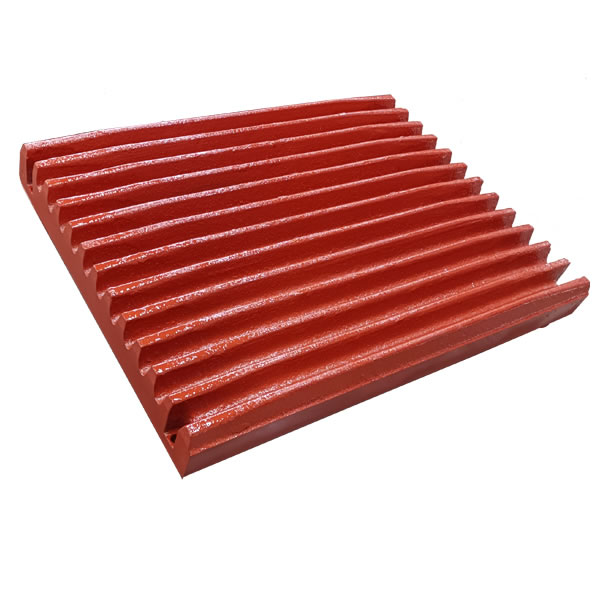

The working mechanism of jaw crusher is composed of working chamber and eccentric shaft composed of movable jaw and fixed jaw. The main accessories are pulley, movable jaw plate, side guard plate, fixed jaw plate, flywheel, eccentric shaft, frame, toggle plate and toggle plate seat, etc.

When the eccentric shaft rotates, the movable jaw plate mainly bears the extrusion of the object, and the static jaw plate mainly bears the sliding cutting of the material.

The side guard plate of the crusher is separated into two sections of upper side guard plate and lower side guard plate. The short side of the upper side guard plate is the same length and parallel to the long side of the lower side guard plate, and the inclination of the bevel of the two side guard plates is consistent. When installing and adjusting, there are specially designed limit blocks and installation holes on both side guard plates to ensure stable installation without displacement. When the jaw crusher is working, the side guard plate made of special materials and specially installed can withstand large impact force without deformation, has good tensile strength and toughness, and effectively ensures the safety of the use of the jaw crusher. The toggle plate of the jaw crusher is a mechanism used to balance and compensate for the wear between the jaw plate, toggle plate and toggle plate pad. The toggle plate can also be used to adjust the size of the discharge port. Under normal circumstances, it only needs to apply a layer of grease on the contact surface between the toggle plate and the toggle plate pad for maintenance.

Zhili New Materials Company mainly produces crusher accessories, mainly hammer heads, blow bars, rotors, liners and cone crusher spare parts. If you need them, please feel free to consult.