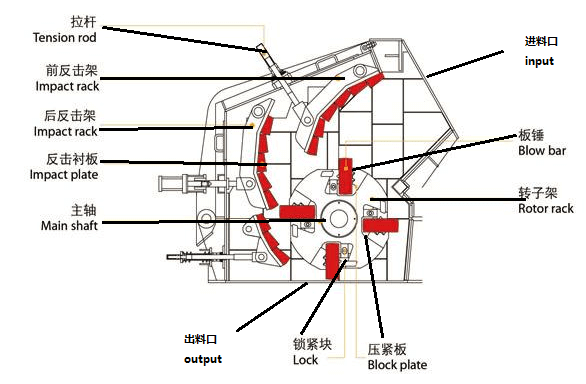

The main parts of impact crusher

Impact crushers are widely used in mining, cement, highway, energy, chemical and other industries.

Impact crushers are named according to their working principle, that is, they use the principle of impact crushing to crush materials. They are a finer crushing equipment than jaw crushers. They are mainly used for fine crushing in stone production lines and work with jaw crushers for crushing.

The main parts of impact crushers include blow bars, impact plates, rotor, square steel, impact liner bolts, flip cover devices, main shafts, locking blocks, clamping blocks, etc.

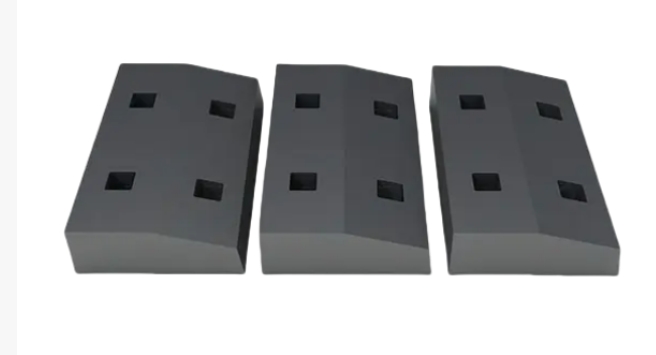

(1) Crusher Rotor

The rotor must have sufficient mass to meet the needs of crushing large pieces of material. The rotor of the crusher is mostly made of integral cast steel structure. This kind of rotor has a large moment of inertia, is strong and durable, is easy to place the hammer, and can meet the requirements of crushing work.

The crusher rotor produced by our company

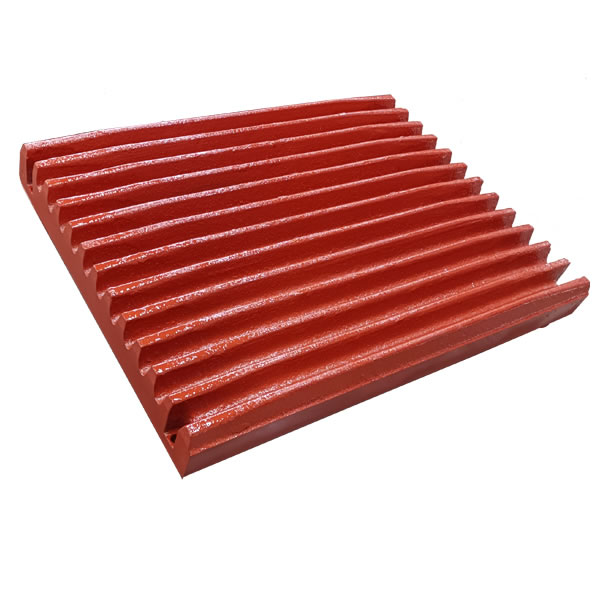

(2) Impact Crusher Blow Bars

The blow bars of the impact crusher is fixed on the rotor. It is an important part of the crusher and requires to be firmly installed and easy to replace. It should be made of materials with good impact resistance, such as high manganese steel, medium carbon alloy steel, bearing steel, etc. Some manufacturers use welding rods to build up a layer on the high manganese steel blow bars or embed alloy inside the blow bars to improve the wear resistance. In recent years, some manufacturers have developed and produced more wear-resistant ceramic composite blow bars.

The blow bars produced by our company

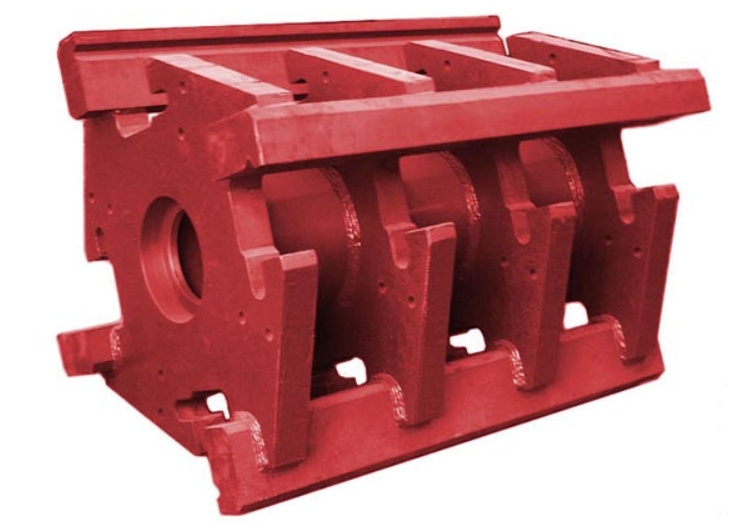

(3) Impact plate

The function of the impact plate is to withstand the impact of the material knocked out by the blow bars and crush it, and bounce the crushed material back to the crushing area for further crushing. The shape and structure of the impact plate have a great influence on the crushing efficiency.

The impact plate produced by our company