Conveyor chute lining

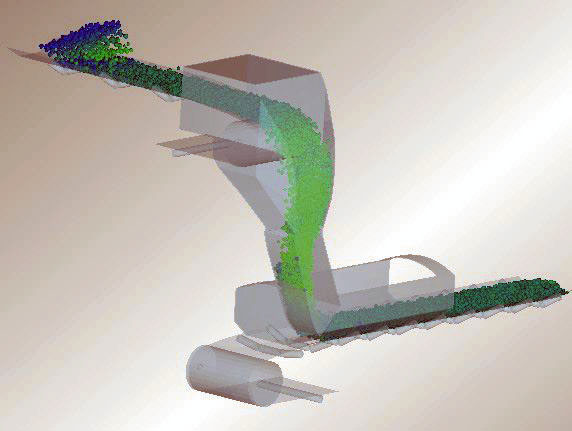

Chutes are widely used in the conveying and storage system of bulk materials. Chutes play an important role in coal mining, connecting coal preparation equipment to allow coal to run along the designed route. Due to the high working intensity and poor working conditions of the chute in the coal preparation plant, the wear resistance and impact resistance of the chute lining are very high. Zhili New Materials Company is specialized in the production of crushing equipment accessories. It has rich work experience and can manufacture high-quality linings to meet the needs of enterprises and extend the service life of the machine.

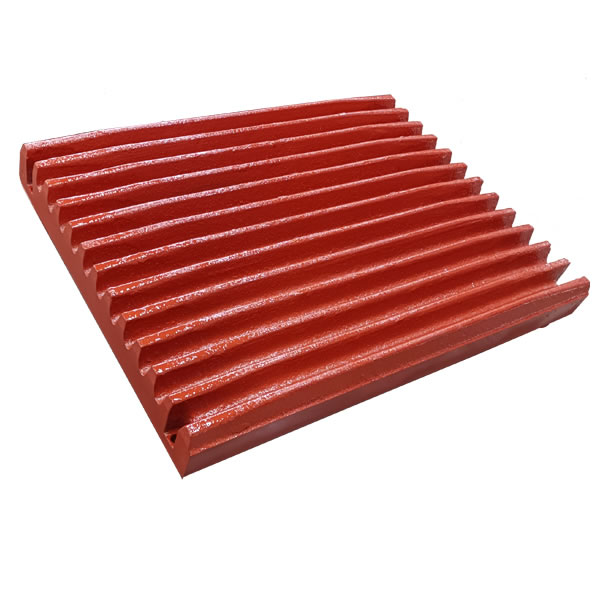

In the design of the chute lining, the equipment motherboard is usually responsible for the structural force, and the special functions of the equipment such as impact resistance and wear resistance require the lining to bear. The selected lining must have strong wear resistance in a specific environment. We will recommend suitable linings to customers based on the materials and characteristics of commonly used wear-resistant linings. The raw coal gangue chute with larger particle size generally needs to be paved with wear-resistant linings, especially the bottom plate and side plates of the inclined section of the chute should be paved with wear-resistant linings, and the height of the side wear-resistant lining is about 2/3 of the height of the side plate. For large gangue chutes, rails can be laid on the bottom plate, which can double the service life of the chute. The higher the hardness of the coal, the stronger the wear resistance and impact resistance of the selected wear-resistant lining. Wear-resistant linings should be laid in chute parts with large drop, strong impact and violent collision. In order to improve the service life of the chute and reduce noise, wear-resistant linings should be laid in the head chute and corners of high-speed and large-volume conveyors that are prone to collision. The wear resistance of alloy steel plates is slightly higher than that of ordinary linings, and the cost is generally about 5 percentage points higher than that of ordinary steel plates. It is mainly used for equipment that needs to be protected by alloy steel wear-resistant materials when passing through the coal surface. Wear-resistant linings are recommended for anti-smashing grilles in gangue bins and wear-resistant grilles at the outlet of spiral chutes. Low-alloy steel linings are mainly used in parts of mechanical equipment where friction occurs, which can greatly improve the service life of the equipment. They can also be used for high-strength structural steel with a yield strength of less than 800Mpa. Wear-resistant steel plates have good gas cutting properties and can be used for gas cutting processing. During machining, the feed amount and feed speed should be reasonably selected according to the hardness of the steel plate and the cutting tool used.

The above is a brief introduction to the chute lining. If you have relevant needs, you can go to the product page of our website for detailed information, or leave a message at the bottom of the page.